Band Saw Accessories

Band Saw Tension Gauge

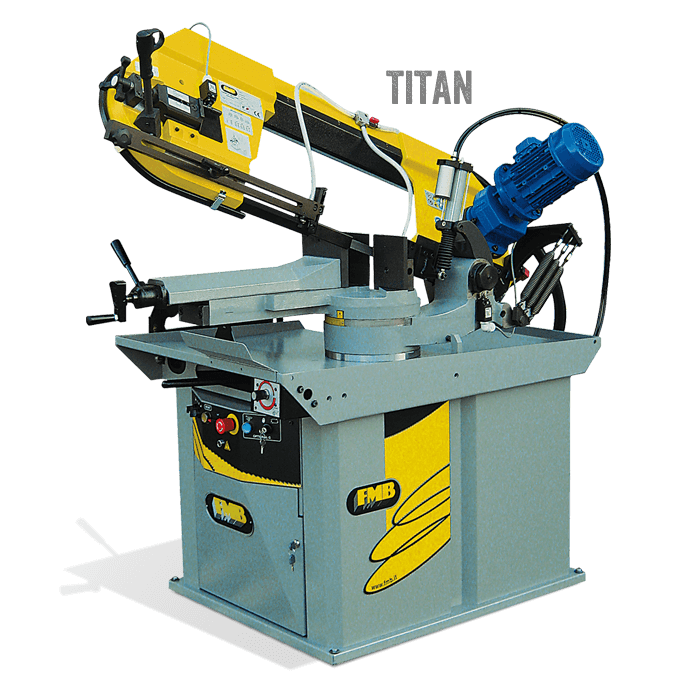

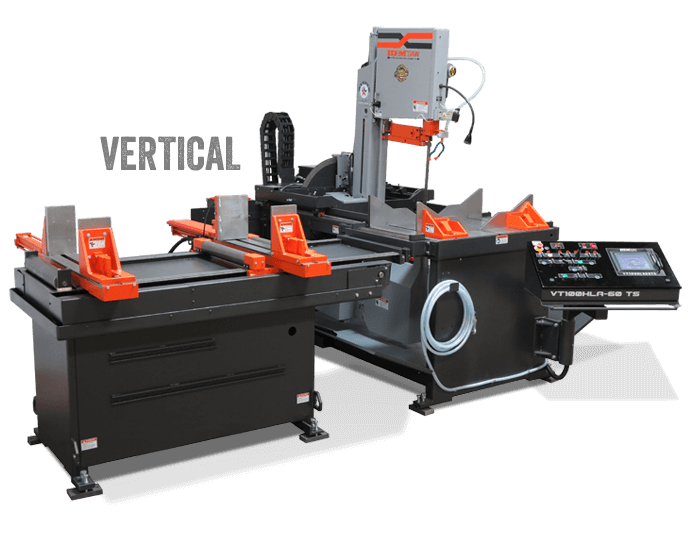

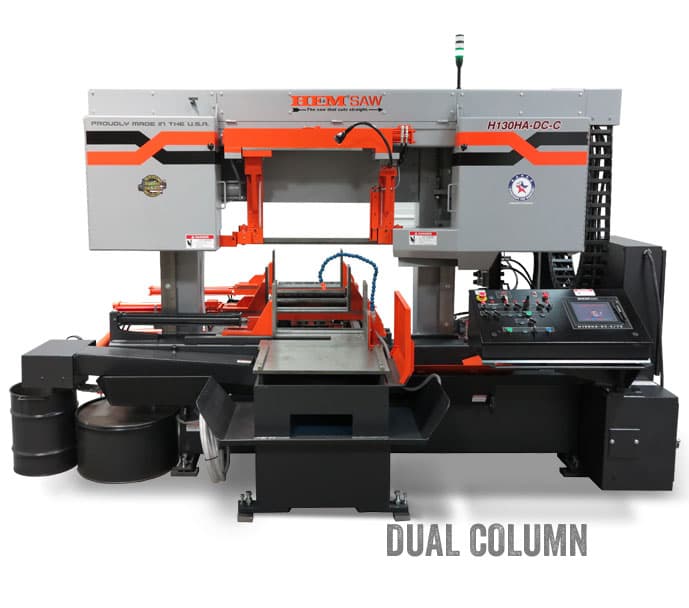

You can also choose from a wide range of Semi-auto band saws. They are available in 27 models, including non-miter and miter versions. These saws are available in either horizontal or vertical models, and can be built to meet high industrial standards.

There are many types of bandsaws for cutting steel, but this article is mainly about the ones for cutting wood and other non-ferrous materials.